Mechanical engineering is undergoing structural change: the focus is no longer on owning a machine, but on its demonstrable performance.

Pay-per-use shifts high upfront investments into plannable, usage-based operating expenses. Companies pay for hours, units or output, gain faster access to up-to-date technology, and can reduce investment risks. For manufacturers, a new earnings profile emerges in parallel: one-off revenues shift to recurring revenues, improving predictability and laying the foundation for service-oriented offerings.

Usage beats ownership – why the model is catching on

Pay-per-use addresses typical hurdles of classic CAPEX acquisitions: liquidity is preserved, costs follow utilization and are therefore more predictable. Especially for small and medium-sized companies with volatile order situations, modern production technology becomes more accessible. From the manufacturers’ perspective, the focus shifts from handing over a machine to its ongoing performance at the customer’s site. This fosters closer, longer-term collaboration and creates starting points for optimizations in operations.

New financial logic for manufacturers and users

While customers can reach profitability faster, the model requires manufacturers to adapt their finance and sales logic. Cash flow is spread over the contract term, which requires careful management during transition phases. Established structures such as sale-and-lease-back or solutions with financing partners help by taking on risk while the manufacturer remains responsible for operations and service. In return, there is room for additional, high-margin services - from software and analytics to consumables.

From supplier to co-operator

With pay-per-use, the customer relationship changes fundamentally. Instead of a one-off transaction, a continuous partnership emerges in which both sides work toward the same goal: maximum availability, high quality and minimal downtime. Regular performance reports, joint reviews and data-driven improvements anchor the manufacturer permanently in the customer’s production and open up cross- and up-selling opportunities that go beyond machine sales.

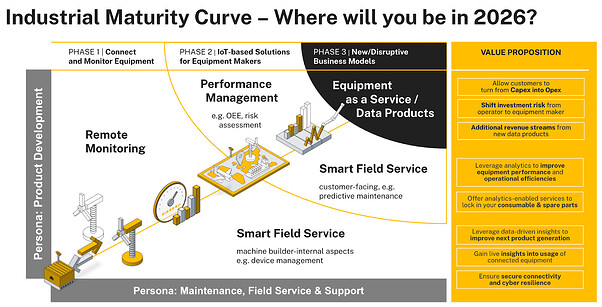

Industrial IoT as an enabler: Cumulocity in practice

Usage-based billing, remote monitoring and predictive maintenance require reliable measurement and data flows. Industrial IoT platforms like Cumulocity connect machines worldwide, capture usage data in real time and make it available for billing, dashboards and service processes. This makes utilization, energy consumption and OEE transparent; alarms, tickets and workflows ensure that disruptions are addressed quickly; anomaly detection enables early identification of irregularities and helps avoid downtime. The same data foundation also forms the basis for continuous optimizations, from adjusting parameters to software upgrades.

From the machine to a service package (EaaS)

In the equipment-as-a-service approach, the machine becomes part of a holistic value proposition. In addition to physical provision, the digital service layer counts: connectivity, transparency about actual use, auditable billing, proactive maintenance and—where agreed—performance-based agreements up to and including output SLAs. Customers benefit from higher efficiency and reduced downtime, manufacturers from more stable revenue streams and faster feedback from the field, which accelerates product development.

Success levers for the transformation

The transition to pay-per-use is not a pure tech project. Standardized data paths, clear usage metrics and a billing model that fits production reality are needed. In the operating model, service KPIs, pricing and risk sharing move to the center; sales focuses more on value selling and SLA arguments; finance looks at profitability over the life cycle. With a focused pilot (clearly defined use case, limited machine base, reliable data capture), the model can be tested in practice and scaled step by step.

We call this the Industrial maturity curve: